TH400-圆环链斗式提升机

技术参数:

料斗尺寸:斗宽400mm,斗距600mm

链条规格:Φ18*50

链轮尺寸:Φ710mm

链速:1.4m/s

物料最大粒径:55mm

- Metallurgy Industry (e.g., sintering ore, hot ores processing)

- Cement and Building Materials Industry (clinker, limestone, fly ash)

- Mining Industry (various mineral processing)

- Power Industry (coal handling in power plants)

For pricing, please contact customer service for a quote.

Basic Info.

Model NO.

| TH400 |

Color

|

Multi Color

|

Condition

|

New

|

Bucket Width

|

400mm

|

Bucket Material

|

Q235B,SUS304,NM400 |

No. of Discharge Port

|

Single or Muti Discharge Port

|

Voltage

|

220~550V

|

Motor Power

|

1.5-22kw

|

Driven Type

|

Electric Motor

|

Transport Package

|

Standard Export Package

|

Material

|

Stainless Steel

|

Application

|

Chemical Industry, Grain Transport

|

Product Name

| Round chain bucket elevator |

Bucket Volume

| 5.9/9.5 L |

Body Material

|

Mild Steel, Stainless Steel 304 or Other

|

Speed

|

Adjustable or Fixed

|

Good Sealing

|

Prevent Environmental Pollution

|

Specification

|

customized

|

Production Capacity

|

200 Sets Per Months

|

Trademark | Ecoshop |

HS Code | 8428391000 |

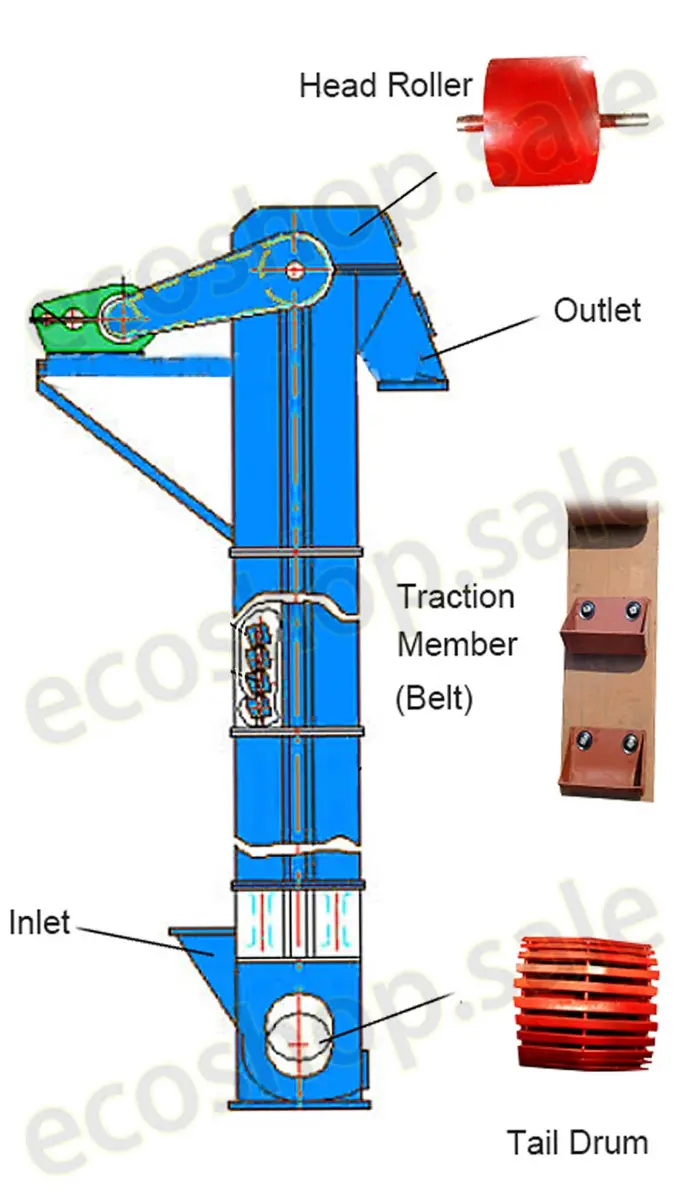

Round Chain Bucket Elevator

The TH-type circular chain bucket elevator is suitable for vertically conveying abrasive powdery, granular, and small lump materials such as grain, coal, cement, crushed ore, etc., with a conveying height of up to 40 meters. Its characteristics include a simple structure, smooth operation, scoop-type loading, mixed or gravity discharge, and the rim can employ a modular sprocket for easy replacement. The sprocket rim undergoes special treatment for extended service life. If a gravity-operated automatic tensioning device is used at the bottom, it can maintain constant tension, preventing slippage or chain detachment. Additionally, in case of obstruction in the hopper, it possesses a certain degree of tolerance, effectively protecting moving parts. The material temperature should not exceed 250°C.

料斗的选择有 Zg 和 Sg 两种,Zg 为中深料斗,Sg 为深料斗,Sg 的输送量比 Zg 大,因此在提升机规格相同的情况下,选择 Sg 料斗,输送量要大一些。但如果物料附着力强,物料潮湿,则应选用 Zg 型料斗,不易积料。

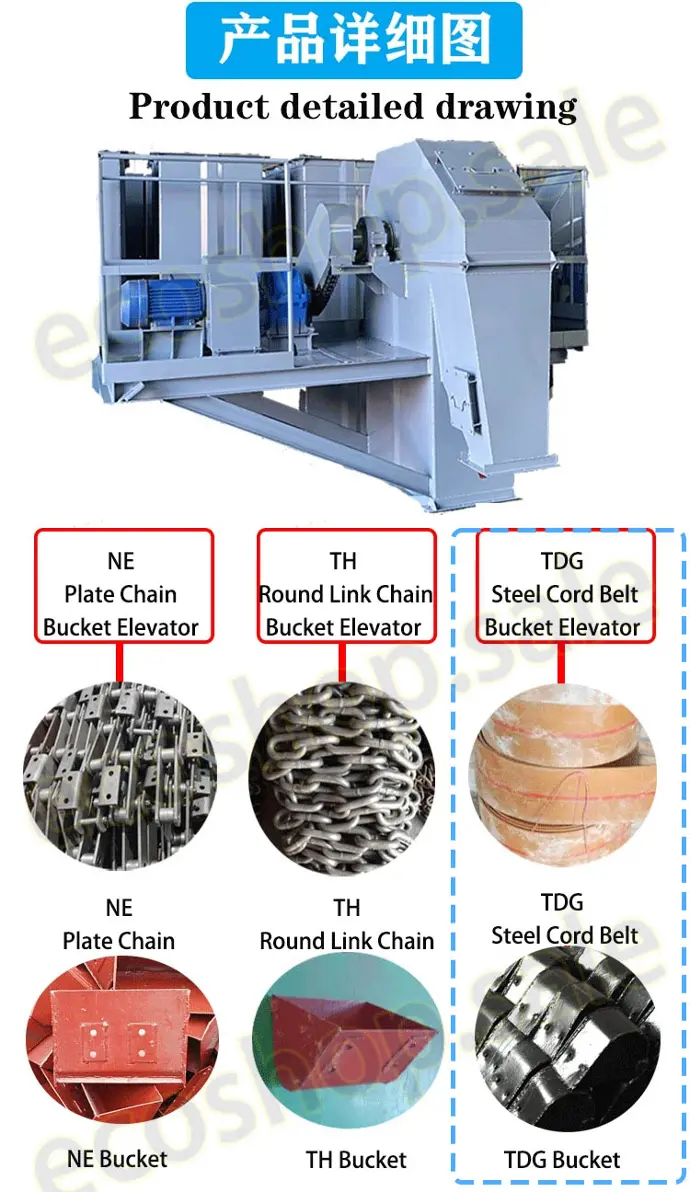

Differences between bucket elevators

TDG 系列

钢丝绳芯胶带斗式提升机--曳引部分为钢丝绳芯输送带,采用离心式或混合式卸料方式,适用于输送堆积密度小于1.5t/m3的粉状、粒状、小块状等非磨蚀性、半磨蚀性物料。使用普通橡胶带时,物料温度不超过 60℃;使用耐热橡胶带时,物料最高温度不超过 150℃。

这种提升机通常用于:

- 食品加工业(如谷物、糖、咖啡豆等)

- 化工行业(非腐蚀性粉末、塑料颗粒)

- 塑料制造业(原料处理)

- 轻工制造业(轻质原材料和成品的搬运)

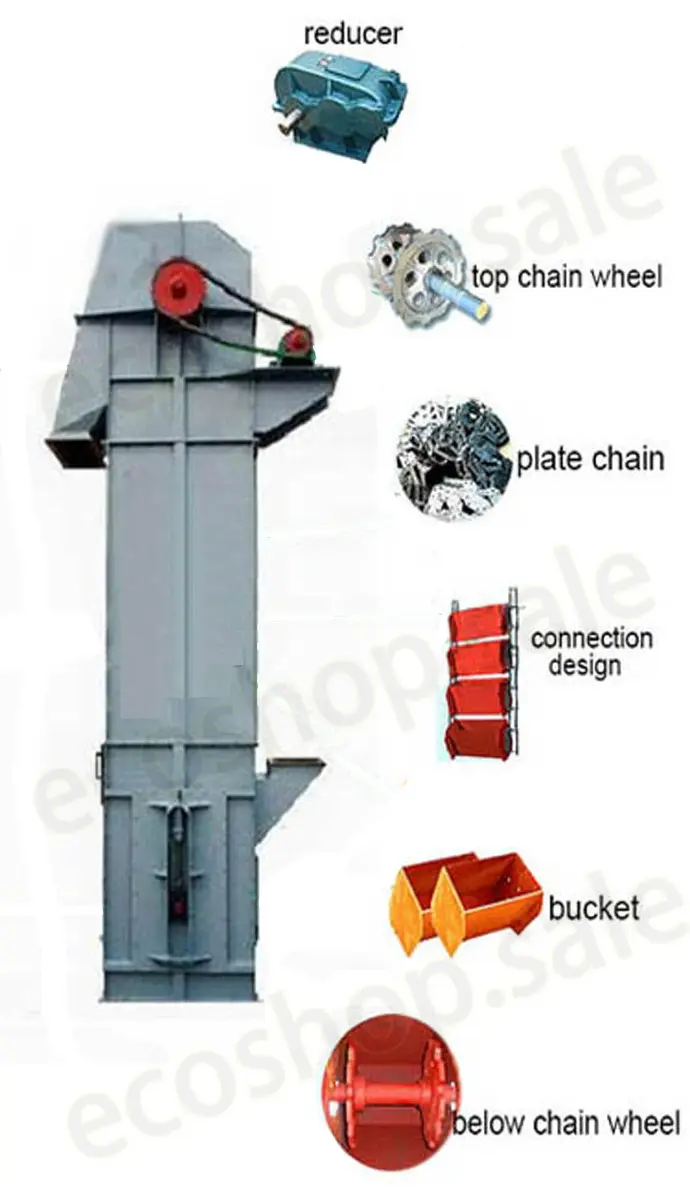

TH 系列

圆环链斗式提升机--曳引部件为高强度圆环链,采用混合式或重力式卸料,适用于输送堆积密度小于 1.5 t/m3 的粉状、颗粒状和小块状的非磨蚀性和半磨蚀性物料,物料温度不超过 250°C。

此类提升机通常用于:

- 冶金工业(如烧结矿、热矿石加工)

- 水泥和建材工业(熟料、石灰石、粉煤灰)

- 采矿业(各种矿物加工)

- 电力工业(发电厂的煤炭处理)

NE 系列

板链斗式提升机--曳引部分为板式套筒滚子链,料斗运行速度为 0.5 m/s,采用重力式卸料方式,适用于输送堆积密度小于 2.2t/m3 的大中型块状磨蚀性物料,物料温度不大于 250°C。

这种提升机通常用于:

- 采矿业(铁矿石、铜矿石等)

- 采石场(碎石、砾石处理)

- 冶金工业(矿渣、矿石提升)

- 建筑材料工业(重型骨料、水泥原料)

比较

总之,使用钢丝绳带的斗式提升机擅长在较低温度下输送轻质、非磨损性物料,是食品和化工行业的理想选择。环链斗式提升机能够承受较高温度,适用于冶金和建筑等行业输送密度适中的物料。板式衬套滚子链斗式提升机设计用于在高温下输送较重的磨蚀性物料,主要应用于采矿和重型制造业。每种类型都针对特定的物料特性和行业需求进行了优化,确保在不同的工业环境中实现高效的垂直运输。