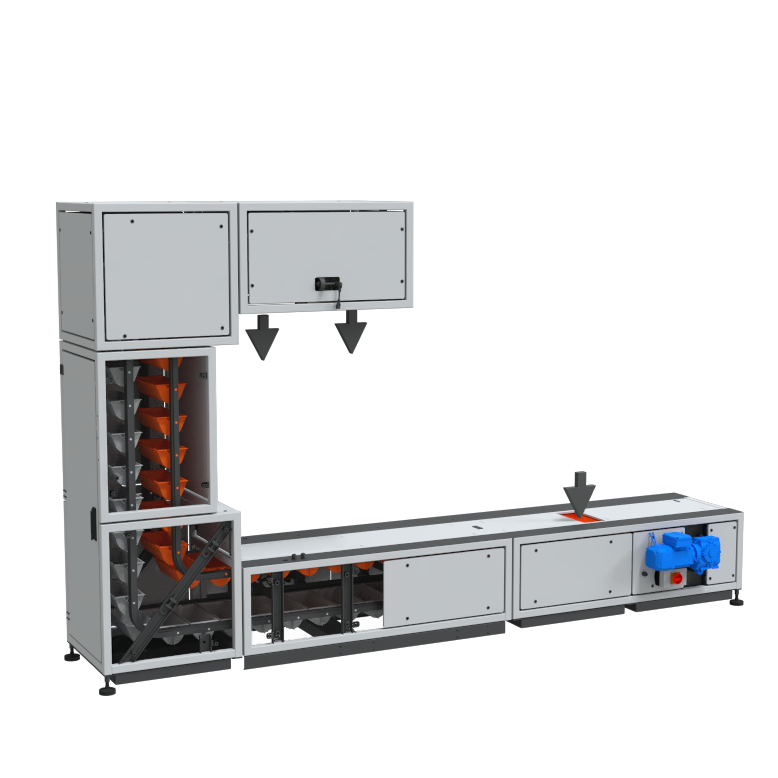

ZBE640-Z型提升机

Basic Info.

Model NO.

|

ZBE640 |

Material Feature

|

Oil Resistant, Heat Resistant, Fire Resistant

|

Condition

|

New

|

Output

|

50-100m3/H

|

Bucket Material

|

PP, ABS, SS304, or Other

|

No. of Discharge Port

|

Single or Muti Discharge Port

|

Voltage

|

220~550V

|

Discharge Height

|

3256 for Standard (1.8L)

|

Lifting Hight

|

Customized

|

Driven Type

|

Electric Motor

|

Transport Package

|

Wooden Case

|

Trademark

| Ecoshop |

HS Code

|

84283200

|

Material

|

Stainless Steel

|

Application

|

Chemical Industry, Grain Transport

|

Product Name

|

Z Type Bucket Elevator

|

Bucket Volume

|

1.0L,1.8L,3.8L,4.8L,5.8L

|

Body Material

|

Mild Steel, Stainless Steel 304 or Other

|

Keword

|

Z Elevator

|

Machine Height

|

3896mm for Standard (1.8L)

|

Speed

|

Adjustable or Fixed

|

Design

|

Z Type/C Type

|

Good Sealing

|

Prevent Environmental Pollution

|

Specification

|

customized

|

Production Capacity

|

200 Sets Per Months

|

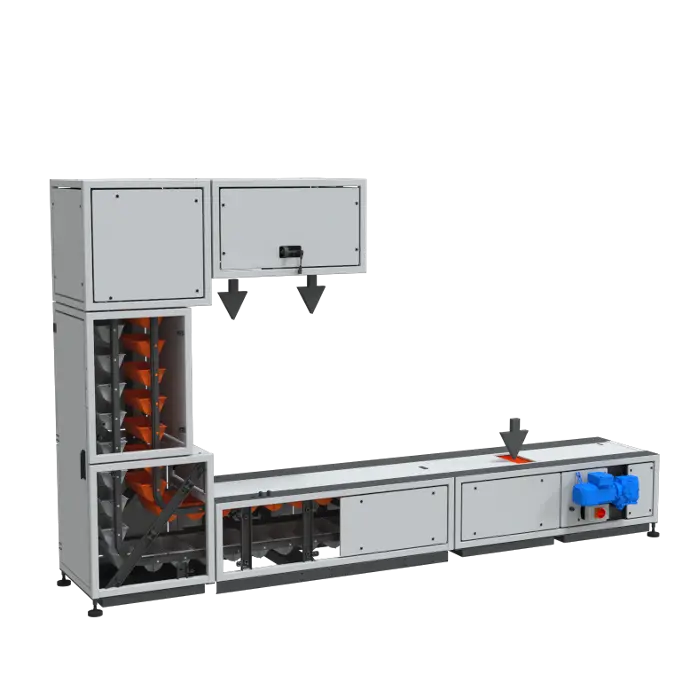

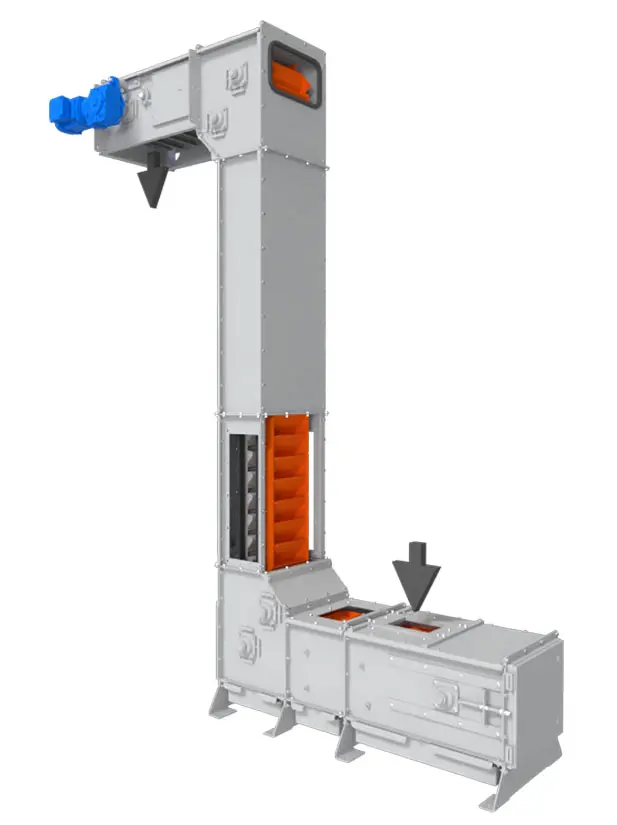

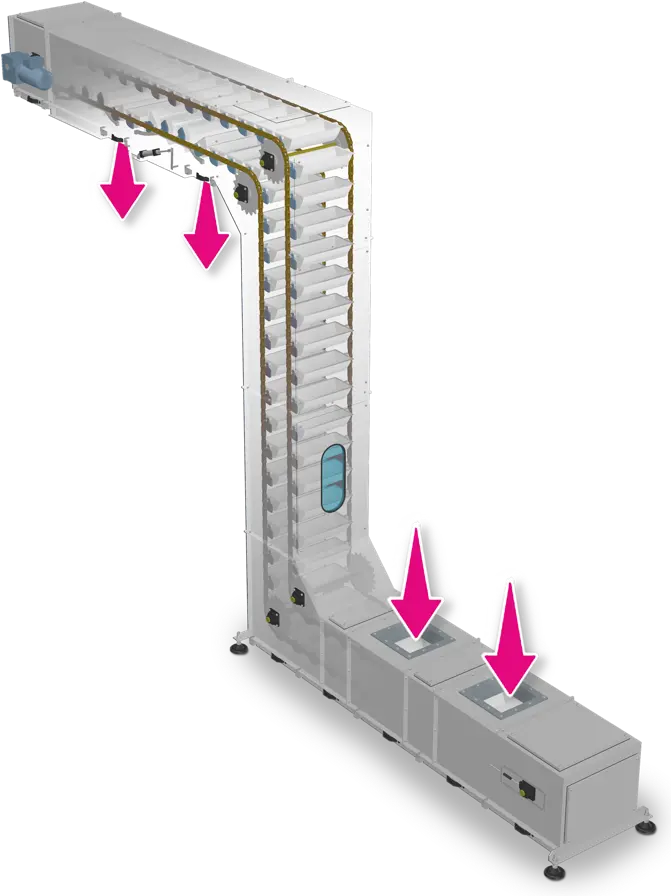

Z Type Bucket Elevator

If you're looking for a machine to help increase the accuracy and efficiency of your supply chain but are limited on space, a vertical bucket elevator could be exactly what you need.

Easy-to-clean and space-efficient, this elevator is a great tool for those who need to deliver powder or small granule materials vertically for additional processing or packaging. Working in conjunction with your weighing and packing machine, helps create a seamless food product quantitative supply and packing system.

Z bucket elevator can be widely applied in horizontal and vertical convey for solid food, such as rice, chip potato, candy feedstuff, and so on.

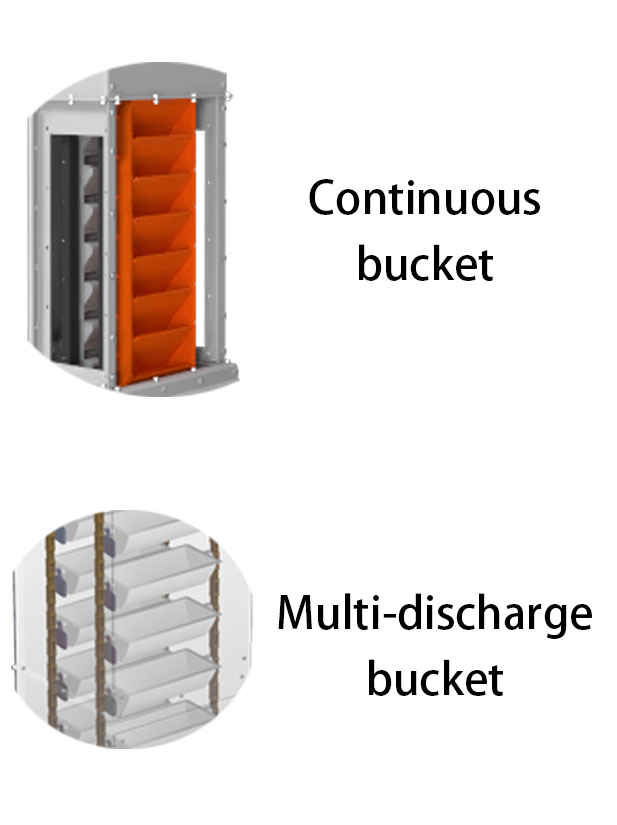

Two transportation methods are optional.

Continuous bucket elevators

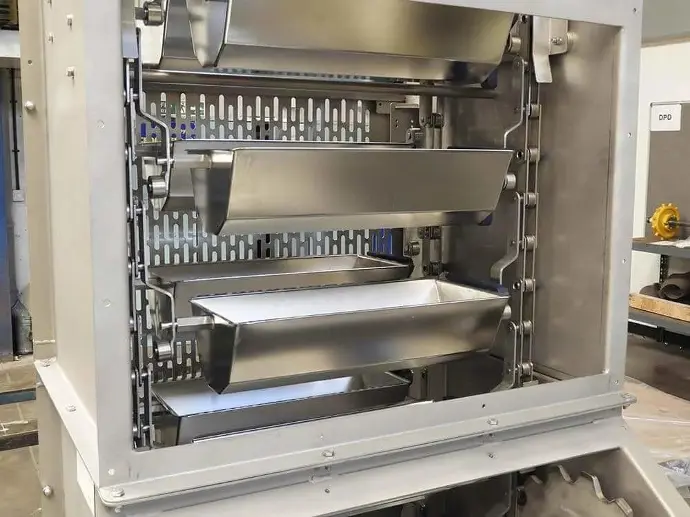

Ecoshop supplying this unique soundless solution for horizontal-vertical-horizontal conveying. Bucket elevators are used for the gentle transport of bulk materials in throughputs up to 200 m3/hour. The elevator consists of a closed bucket belt in which the buckets are interconnected by means of flexible connectors, so that spillage is reduced to a minimum. The bucket elevator transports materials from various in feed points to one central discharge point.

Multi-discharge bucket elevators

Multi-discharge bucket elevators have the same capacities and are used in the same areas of application as bucket elevators. This type of bucket elevator can be loaded at various infeed points but, unlike the bucket elevator, the buckets can be discharged separately at various discharge points. At the discharge points, the buckets are individually (for example pneumatically) turned over. An additional application possibility of these elevators is their use as dosing unit for packaging, weighing ore counting systems.

Contrary to the bucket elevators, the buckets are not interconnected so that they can turn over individually.

Continuous bucket elevators

VS

Multi-discharge bucket elevators

Continuous bucket elevators utilize custom-molded rubber chains (with steel wire cores) and tailored PP buckets, offering distinct advantages in the feeding stage. The seamless connection between buckets ensures no leakage or shaking, resulting in a more stable material transport. However, they are designed to support single-point discharge only.

Multi-discharge bucket elevators, with their primary advantage, support multi-point feeding as well as multi-point discharging. This allows for greater flexibility and adaptability in various material handling scenarios, enabling the buckets to be loaded at numerous infeed points and subsequently discharged individually at distinct discharge points.

Product Features

1. All elevators are equipped with an automatic chain tension device and built-in overload protection.

2. Material of structure: Stainless steel 304 or carbon steel or others as required.

3. The buckets are made of PP, ABS, stainless steel 304, or others as required.

4. Feed automatically, so it reduces material leakage and damage.

5. The conveyor is controlled automatically.

Product Application