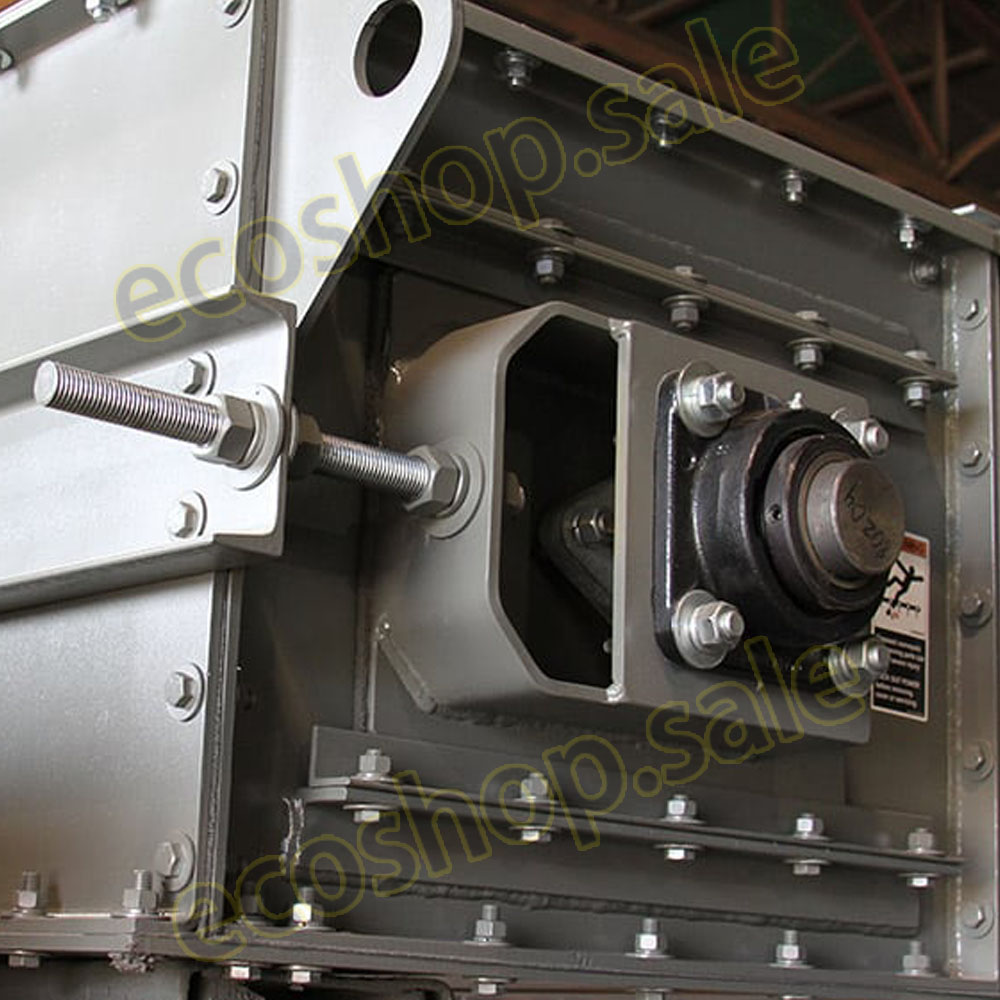

MS50-Drag Chain Conveyor

Main technical parameters:

Trough width: 500mm;

Maximum material layer height: 400mm;

Conveying efficiency: 0.65~0.75;

Chain pitch: 200mm.

Basic Info.

Model NO.

| MS16 |

Trough width |

160mm |

Condition

|

New

|

Output

|

11-25m3/h |

Chain Material

|

40Cr,35CrMo,20CrMnTi, Other

|

No. of Discharge Port

|

Single or Muti Discharge Port

|

Voltage

|

220~550V

|

Lifting Hight

|

Customized

|

Driven Type

|

Electric Motor

|

Transport Package

|

Wooden Case

|

Trademark

| Ecoshop |

Material

|

Stainless Steel

|

Product Name

|

Drag Chain Conveyor |

Chain Pitch |

100mm |

Body Material

|

Mild Steel, Stainless Steel 304 or Other

|

Keword

| Drag Chain Conveyor |

Speed

|

Adjustable or Fixed

|

Good Sealing

|

Prevent Environmental Pollution

|

Specification

|

customized

|

Production Capacity

|

200 Sets Per Months

|

HS Code | 84283200 |

MS Type Drag Chain Conveyor

Drag chain conveyor is a continuous conveying equipment used for transporting dusty, small granular, and small blocky bulk materials, capable of horizontal, inclined, and vertical conveying. During conveying, the drag chain is completely buried in the material, hence the name drag chain conveyor. Bulk materials possess characteristics such as internal friction and lateral pressure. During horizontal conveying, the material is subjected to the thrust force of the drag chain in the direction of motion. When the internal friction between the material layers is greater than the external friction between the material and the wall of the trough, the material moves forward with the drag chain. When the ratio of the material layer height to the trough width meets certain conditions, the material flow is stable.

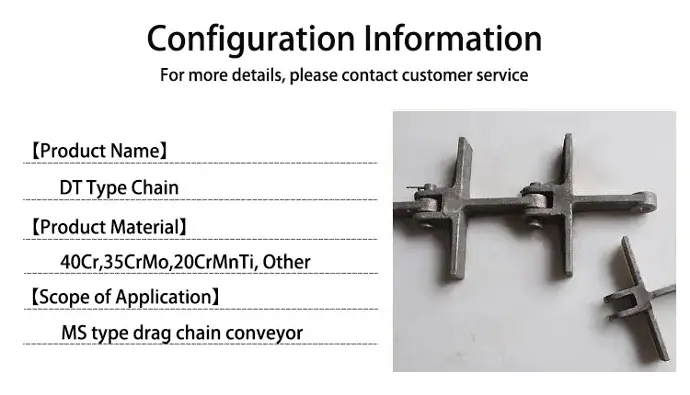

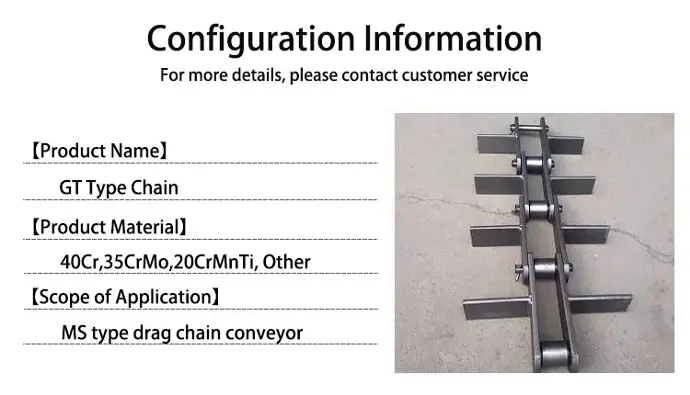

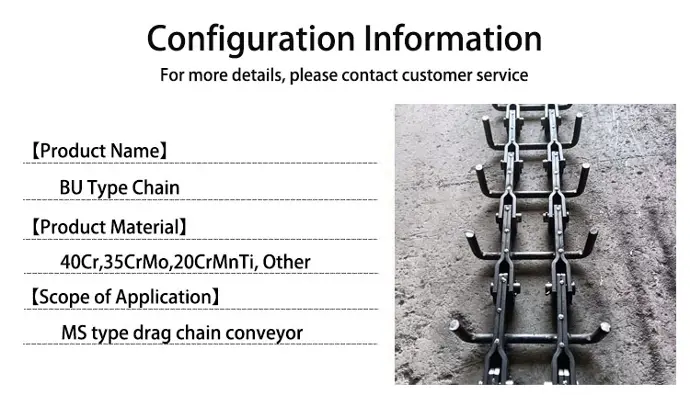

Difference in chain form

between MS Drag Chain Conveyors

DT Type Chain

For materials with good conveying performance or not too large particle size, simple scraper types such as T-shaped, V-shaped, and O-shaped can be selected;

Chain links are drop-forged for maximum strength.

GT Type Chain

For materials with good conveying performance or not too large particle size, simple scraper types such as T-shaped, V-shaped, and O-shaped can be selected;

Chain links are made of plate chain with medium strength

BU Type Chain

For materials with high suspensibility and fluidity, to ensure that sufficient internal friction can be generated between materials to overcome external resistance and self-weight, more complex scraper types such as U-shaped or O-shaped should be selected;

Chain links are welded with double-row plate chains for maximum strength