TH400-円形チェーンバケットエレベーター

技術パラメータ:

ホッパーの寸法:幅400mm、間隔600mm

チェーンの仕様:Φ18*50

スプロケットのサイズ:Φ710mm

チェーンの速度:1.4m/s

材料の最大粒径:55mm

- Metallurgy Industry (e.g., sintering ore, hot ores processing)

- Cement and Building Materials Industry (clinker, limestone, fly ash)

- Mining Industry (various mineral processing)

- Power Industry (coal handling in power plants)

For pricing, please contact customer service for a quote.

Basic Info.

Model NO.

| TH400 |

Color

|

Multi Color

|

Condition

|

New

|

Bucket Width

|

400mm

|

Bucket Material

|

Q235B,SUS304,NM400 |

No. of Discharge Port

|

Single or Muti Discharge Port

|

Voltage

|

220~550V

|

Motor Power

|

1.5-22kw

|

Driven Type

|

Electric Motor

|

Transport Package

|

Standard Export Package

|

Material

|

Stainless Steel

|

Application

|

Chemical Industry, Grain Transport

|

Product Name

| Round chain bucket elevator |

Bucket Volume

| 5.9/9.5 L |

Body Material

|

Mild Steel, Stainless Steel 304 or Other

|

Speed

|

Adjustable or Fixed

|

Good Sealing

|

Prevent Environmental Pollution

|

Specification

|

customized

|

Production Capacity

|

200 Sets Per Months

|

Trademark | Ecoshop |

HS Code | 8428391000 |

Round Chain Bucket Elevator

The TH-type circular chain bucket elevator is suitable for vertically conveying abrasive powdery, granular, and small lump materials such as grain, coal, cement, crushed ore, etc., with a conveying height of up to 40 meters. Its characteristics include a simple structure, smooth operation, scoop-type loading, mixed or gravity discharge, and the rim can employ a modular sprocket for easy replacement. The sprocket rim undergoes special treatment for extended service life. If a gravity-operated automatic tensioning device is used at the bottom, it can maintain constant tension, preventing slippage or chain detachment. Additionally, in case of obstruction in the hopper, it possesses a certain degree of tolerance, effectively protecting moving parts. The material temperature should not exceed 250°C.

There are two types of hopper selection Zh and Sh, Zh is a medium-deep hopper, Sh is a deep hopper, Sh has a larger capacity than Zh, so with the same specifications of the elevator, the selection of Sh hopper, the conveying capacity should be larger. But if the material is strong adhesion, with humid material, then select type Zh hopper, less easy to accumulate material.

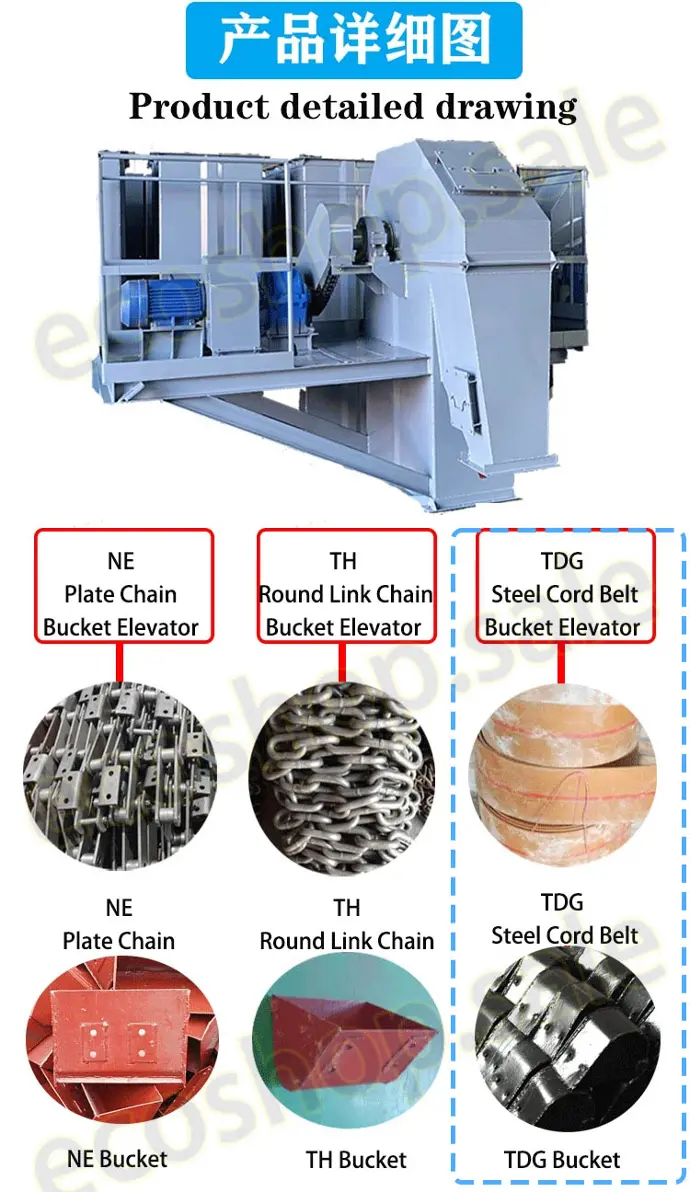

Differences between bucket elevators

TDG Series

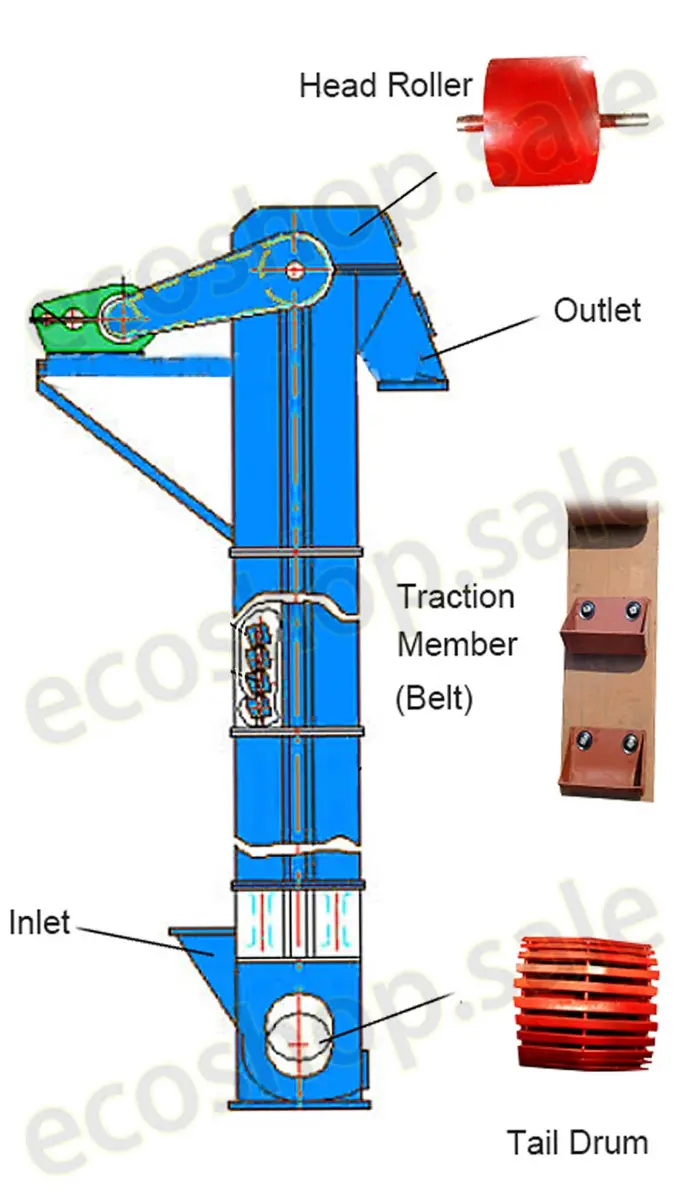

Steel Cord Belt Bucket Elevator--The traction part is steel cord core conveyor belt, adopting centrifugal or mixing method of discharging, which is suitable for conveying non-abrasive and semi-abrasive materials in the form of powder, granule and small block with the accumulation density less than 1.5t/m3. When ordinary rubber belt is used, the material temperature should not exceed 60℃; when heat-resistant rubber belt is used, the maximum material temperature should not exceed 150℃.

this type of elevator is commonly found in:

- Food Processing Industry (such as grains, sugar, coffee beans)

- Chemical Industry (non-corrosive powders, plastic granules)

- Plastics Manufacturing (raw material handling)

- Light Manufacturing (handling of light raw materials and finished products)

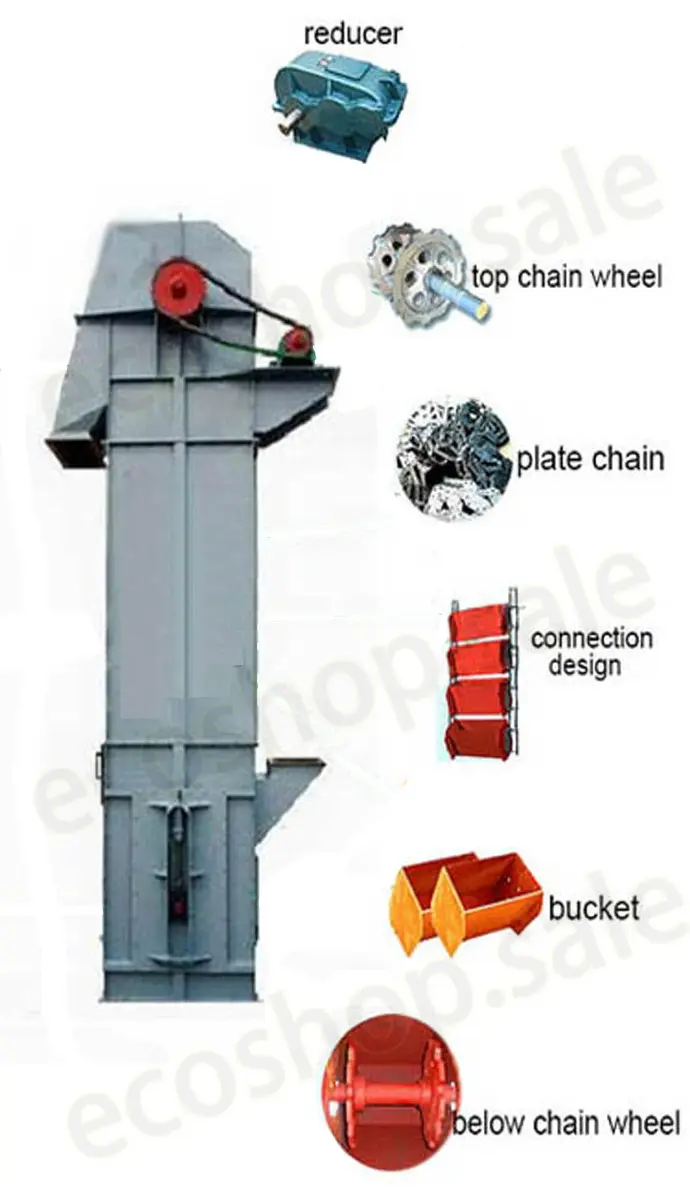

TH Series

Round Chain Bucket Elevator--The traction parts are high-strength round ring chain, adopting mixed type or gravity type discharging, suitable for conveying non-abrasive and semi-abrasive materials of powder, granule and small block with the bulk density less than 1.5 t/m3, and the temperature of the materials should not be more than 250°C.

this type of elevator is commonly found in:

- Metallurgy Industry (e.g., sintering ore, hot ores processing)

- Cement and Building Materials Industry (clinker, limestone, fly ash)

- Mining Industry (various mineral processing)

- Power Industry (coal handling in power plants)

NE Series

Plate Chain Bucket Elevator--The traction part is plate sleeve roller chain, the running speed of the hopper is 0.5 m/s, and it adopts gravity type discharging method, which is suitable for conveying the medium and large lumpy abrasive materials with the stacking density of less than 2.2t/m3, and the temperature of the materials should not be more than 250°C.

this type of elevator is commonly found in:

- Mining Industry (iron ore, copper ore, etc.)

- Quarry Industry (crushed stone, gravel handling)

- Metallurgy Industry (slag, ore lifting)

- Construction Materials Industry (heavy aggregates, cement raw materials)

Comparison

In summary, bucket elevators utilizing steel cord belts excel in handling light, non-abrasive materials at lower temperatures, making them ideal for food and chemical industries. Ring chain bucket elevators, capable of withstanding higher temperatures, are suited for transporting moderately dense materials in sectors like metallurgy and construction. Plate bushed roller chain bucket elevators, designed for heavier, abrasive materials at elevated temperatures, find their application predominantly in mining and heavy manufacturing. Each type is optimized for specific material characteristics and industry demands, ensuring efficient vertical transportation in diverse industrial settings.